3d打印解决方案

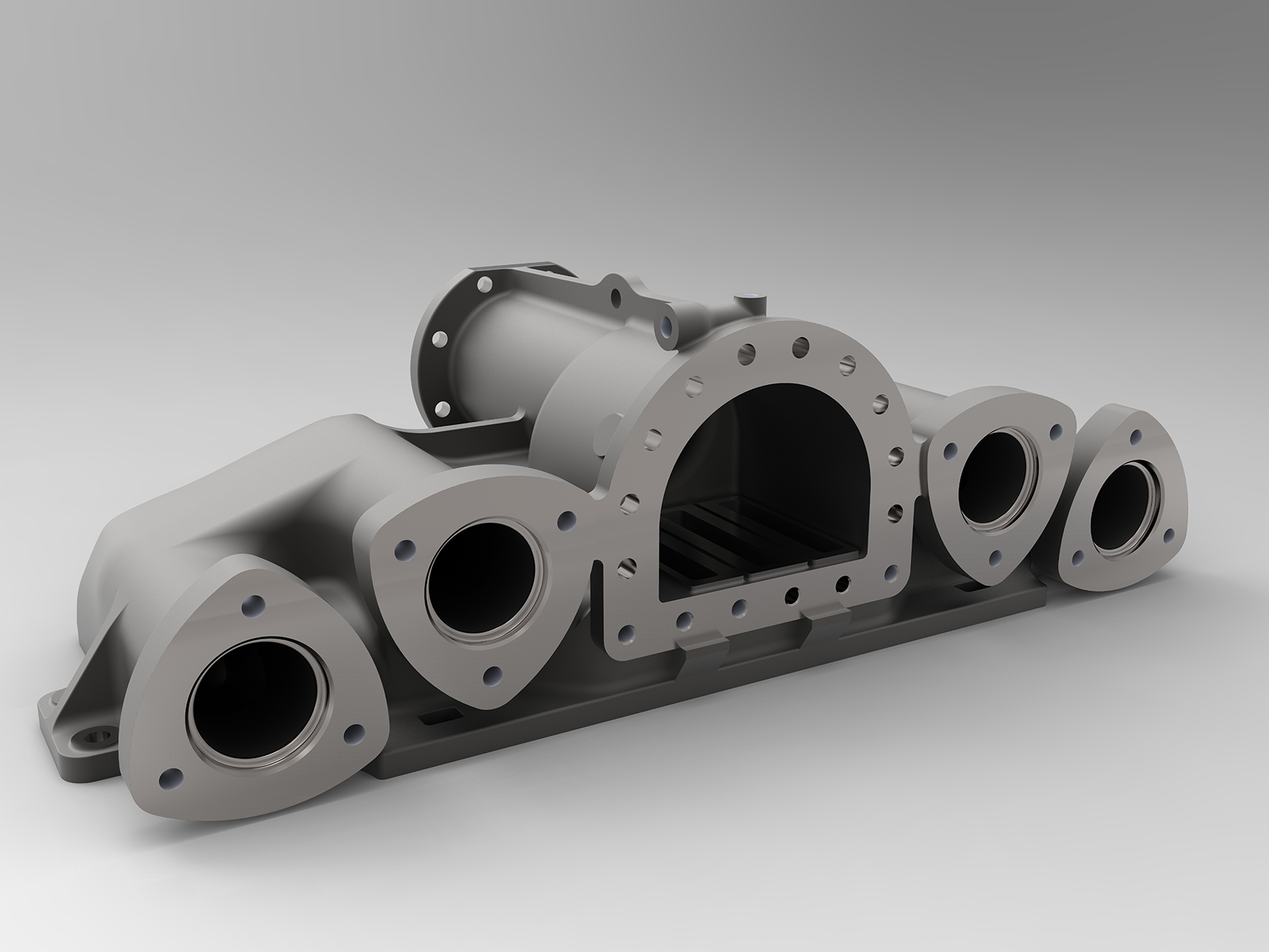

砂型3D打印铸造,速度快,成本低。

砂型3D打印技术确保最佳的铸造效果

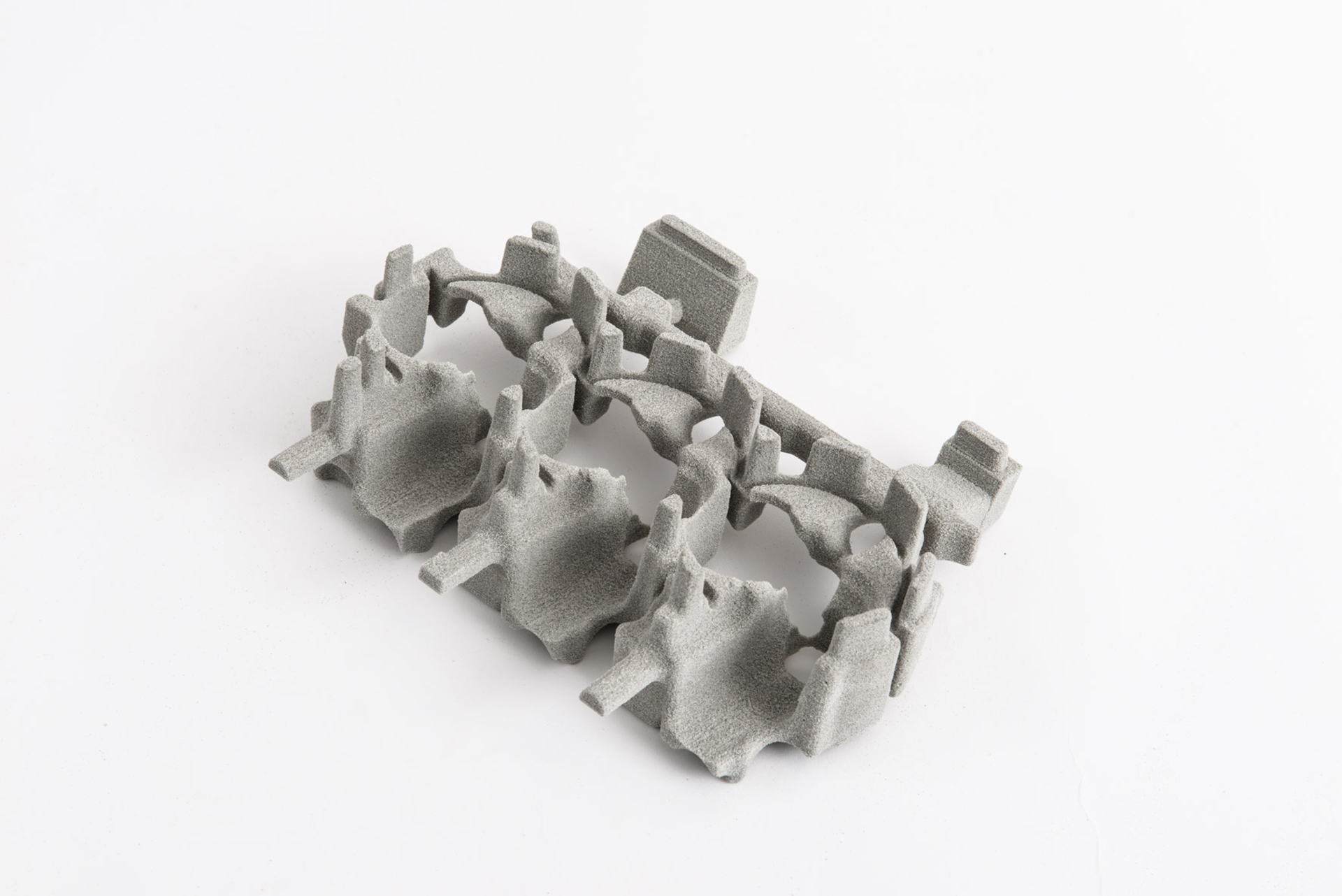

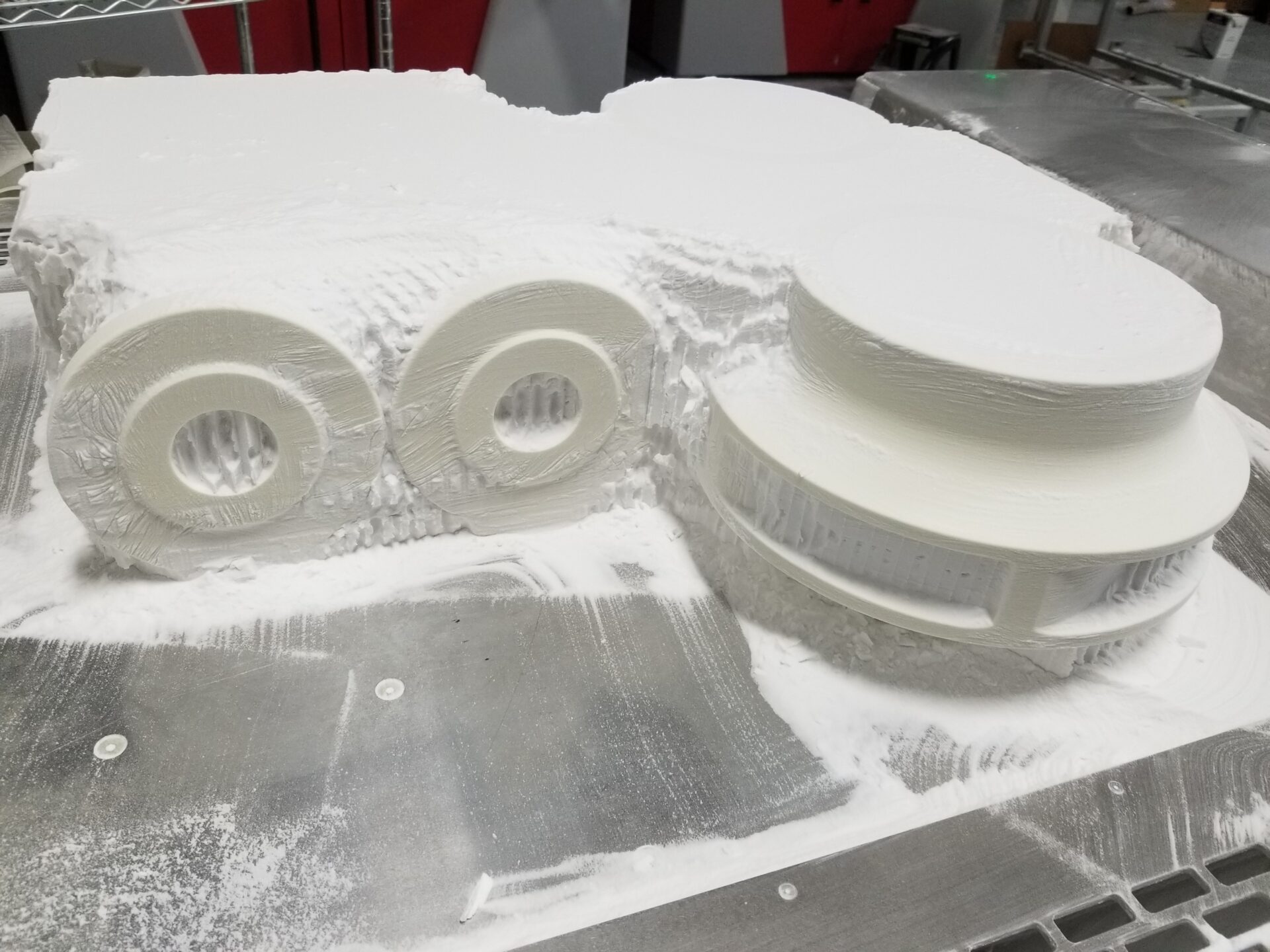

铸造行业正处于动荡的状态。能否生产出越来越复杂的形状、不稳定的数量和较短的交货时间,正成为竞争中成功的重要因素。即使在数字化时代,世界也不是二进制的。voxeljet在此专注于将经典铸造砂型3D打印技术与灵活的快速成型生产工艺进行智能融合。以实现整个生产增值链的持续优化和效率提升。从原型设计、零配件生产到敏捷的工业系列化生产。凭借通用粘合剂喷射三D打印技术,以及经典金属铸造工艺的砂模和型芯的无工具生产,我们为铸造行业开辟了新的天地。不受个性化、轻量化结构和苛刻或复杂几何形状的限制。而且不要忘了在制造过程中具有巨大的成本优化潜力。

砂型3D打印技术确保最佳的铸造效果

优化成本

复杂的几何形状和越来越多的变化和更小的批量尺寸。在传统工艺因成本密集型模具建造或更换时间而达到经济极限的情况下,3D生产工艺具有重要的经济优势。完全数字化生产,不需要工具,在计算中,下料或牵伸角度失去了重要性,可以以优化的成本进行生产。

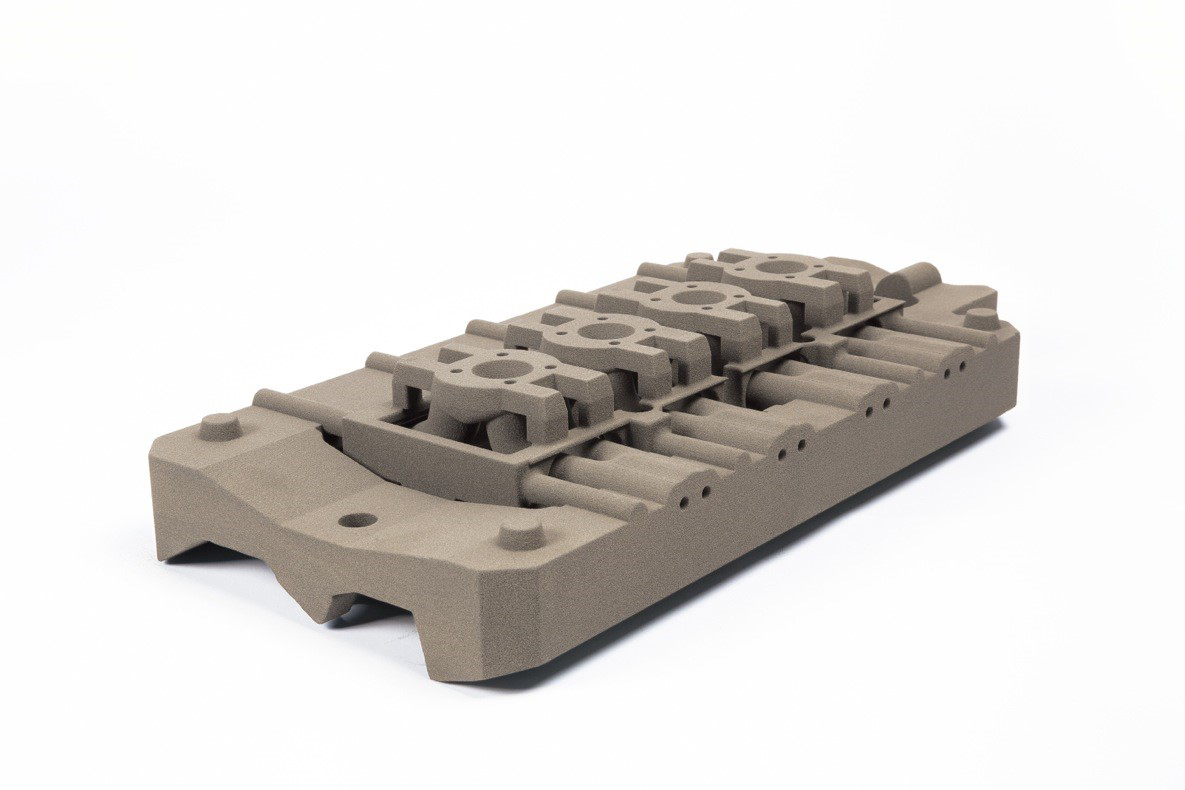

任何规模的生产

voxeljet拥有世界上最大、最强大的3D打印系统,可用于大型部件或小部件的大量运行。我们克服了传统3D打印系统和工艺的局限性。使用常见的铸造材料,如砂子和补充粘结剂,通过与传统生产工艺的无缝集成,确保最佳的铸造效果。

加快上市时间

通过消除对工具和模具制造的需求,快速成型生产工艺可将部件的制造时间缩短75%。3D打印工艺使它们可以在一个紧凑的生产步骤中制造出来。砂模和型芯可以在短短几个小时内生产出来。这意味着可以节省几周的时间。

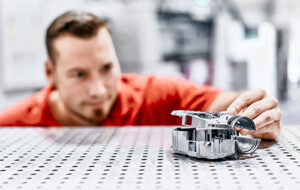

通过使用voxeljet的粘结剂喷射技术,我们可以为客户大大缩短模具和型芯的交付时间。此外,我们在铸件的尺寸和重量方面也创造了新的记录。

Oliver Johnson, CEOTEI

TEI,美国依靠voxeljet混合制造

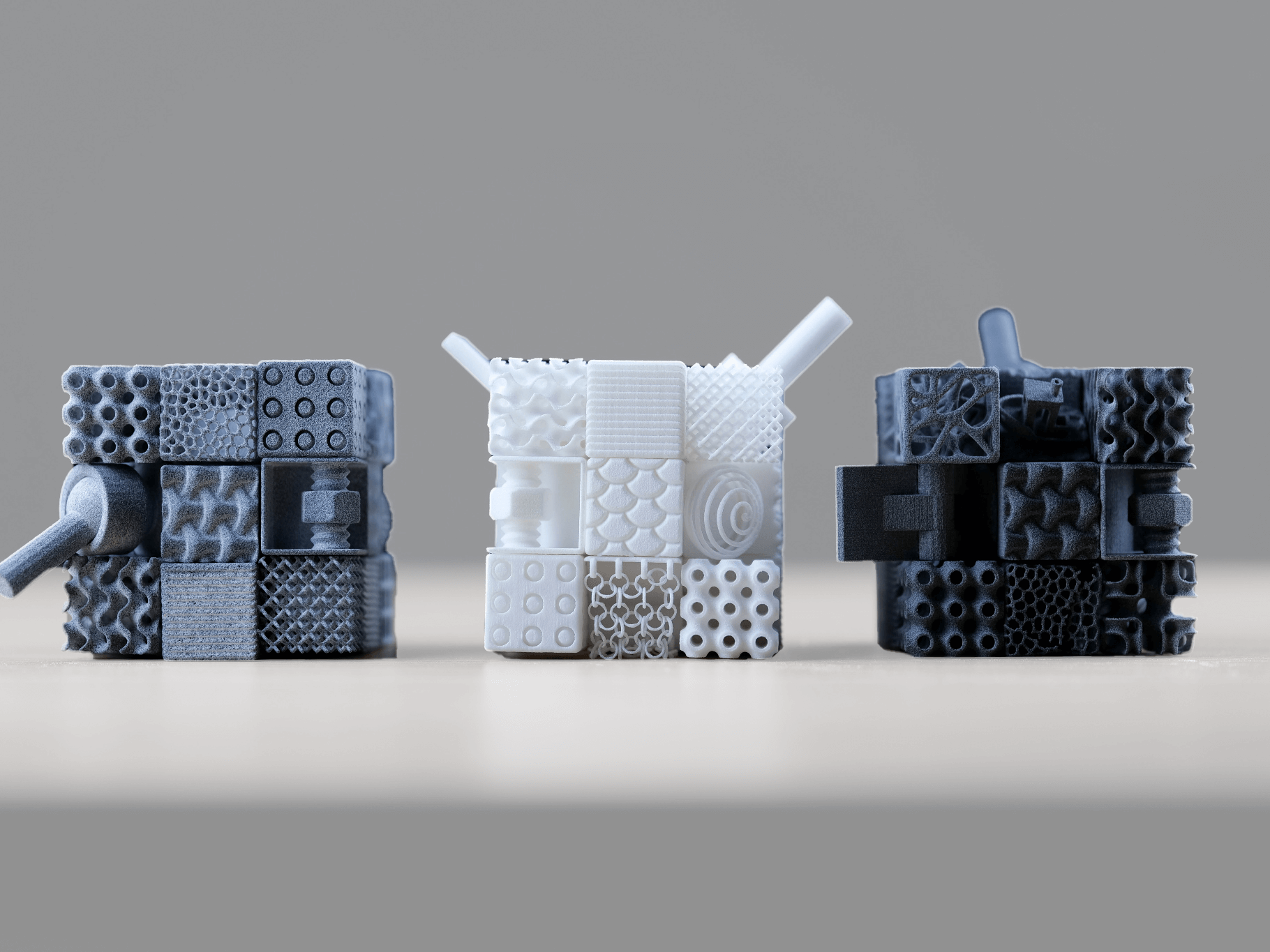

我们的添加剂砂型铸造系统模子和芯子

voxeljet在这个过程中为您提供支持,从用于生产中等规模系列订单的快速原型、高效机器,到世界上最大、最强大的3D打印系统,用于大型部件或小部件的大批量增材生产。具有多种可能的砂/粘结剂组合,并可自由选择基于呋喃、酚醛树脂或无机粘结剂的制造方式。您还可以通过我们的全球3D服务中心获得模具和芯材,以彻底测试工艺,而无需自己投资硬件,并优化产品或加速其开发。

3D砂型铸造。材料:

当涉及到在专业或工业环境中建立3D生产过程时,voxeljet是第一时间的先锋之一,voxeljet 3D打印系统配备了最新的技术,可以24/7运行。我们的通用粘合剂喷射机,专门为工业用途开发,是全球市场上最好的产品之一。特别是当产量、效率和生产速度非常重要的时候。以下是一些已经通过砂型铸造添加剂生产认证的材料。

voxeljet在铸造行业的亮点

Express Prototyping 是北美投资铸造模型三维打印领域的领先专家之一。了解总经理 Thomas Müller 如何创建公司以及他对未来的展望。

在韩国光桥画廊(Galleria Gwanggyo)独特的外墙设计中,采用了三维打印和熔模铸造技术,为玻璃步道制作了数百个独立的连接节。

现代结构优化与 3D 打印和钛投资铸造相结合。这些踏板曲柄展示了消除现有设计限制的可能性。

三维打印与模板施工完美结合。voxeljet 为黑森林博物馆的建筑增材制造设定了新标准。

英国铸造厂Boro Foundry利用砂型和3D打印的结合,为蒸汽机车生产了一个无缺陷的备件。

HSS材料网发布了一个新的概念证明。来自制造商Launhardt的TPU是市场上最柔软的材料之一。

工业聚合物3D打印评论。voxeljet HSS、HP MJF和SLS的广泛比较

HSS、MJF和SLS聚合物3D打印之间有什么区别?在这个广泛的比较中了解聚合物的三种主要AM技术。

支持与服务

您对3D打印在生产中的创新应用有具体问题吗?您想自主维护机器或鉴定新材料吗?您关于如何利用增材制造技术优化生产的问题是维捷的首要问题。